One of the standard gripes about modern manufacturing is how many items break down because the manufacturer saved a very small fraction of the price, sometimes only a few cents. I find myself frequently resoldering mice and headphones, presumably because the wires were too thin, but there at least there is a functionality benefit from thin wires.

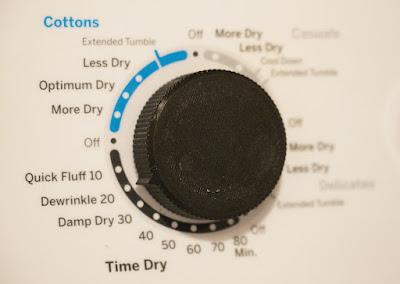

The most recent is our GE dryer where the timer knob always felt flimsy, and finally the plastic holding the timer shaft cracked. The underside revealed thin-walled plastic holding the timer shaft, reinforced with some more chambers made of thin-walled plastic. Perhaps over-reacting, I ended up designing a very chunky 3D-printed one.

I suppose there is an environmental benefit from using less plastic, but it needs to be offset against the environmental cost of repair and replacement. Adding ten grams of plastic would have easily made the knob way, way stronger, and that's about 0.01 gallons of crude oil, which is probably an order of magnitude less than the crude oil someone might use to drive to the store for a replacement (or a repair person being called in; in our case, it wasn't obvious that the knob was the problem; I suspected the timer at first, and disassembled it, before finally realizing that the knob had an internal crack that made it impossible for it to exert the needed torque).

2 comments:

In hindsight, I could have just downloaded something from Thingiverse. But it was fun to design, and I like the knurling (based on an arcade spinner I'm making for Tempest).

Post a Comment